I like to build wheels, it’s fun and relaxing. Over the last few years, I’ve drooled over the snazzy wheel lacing jigs offered on some websites, but the prohibitive cost has held me back, especially considering that they are clearly made from off-the-shelf extrusions and a small collection of custom parts.

The dimensions were also a factor, although I could probably derive the dimensions fairly easily, I can be lazy. I stumbled across a site that listed the dimensions of a jig, and with beer in hand, I sat down to peruse 8020.net and do a bit of extrusion shopping. The 8020 catalog is like an erector set for grown-ups, with all sorts of very cool stuff to play with. Extrusions, hardware, panels, designs…this stuff is like candy.

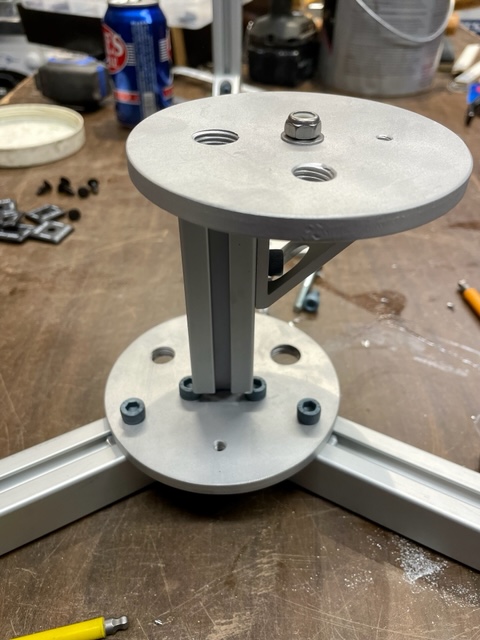

There are 2 challenges to using an extrusion system that is designed for 90-degree connections: a 3-legged stand connects at 120-degrees, and 8020 does not have such a part, and there needs to be a method of holding the hub in the center of the jig. Most commercial designs use custom spindles for 5mm (quick release), 12mm, and 15mm axle sizes, but being a MAMIL, I didn’t want to spend the money to custom mill those parts. Instead, I used a turntable design I thought up with my own two braincells.

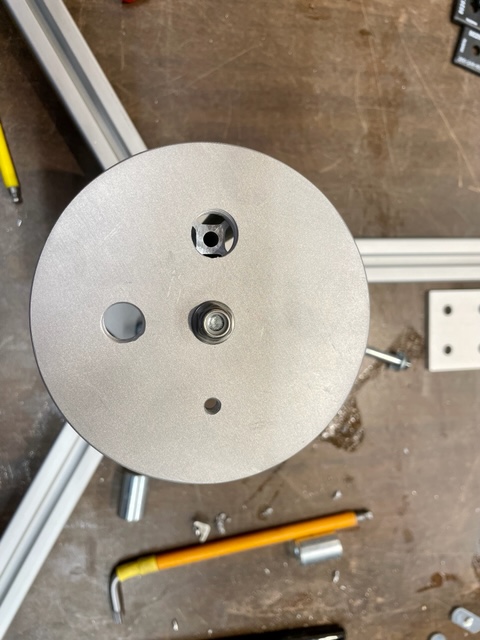

Basically, the turntable would spin around the center of the jig, and be threaded for 5mm, 12mm, and 15mm axles, all of which are typically included with the bike frame. By using a 90-degree bracket on the centerpost as a pivot point, I could simply make a disc with 3 tapped holes. The disk needed to be thick enough for threading, so I decided on 1/4″.

I ordered up the pieces I needed, except for the central connector and top plate. For these I turned to eBay, which can be a pain in the ass, but is also a decent place to find small quantities of specialized parts. It was easy to find 2 discs of aluminum, 4″ in diameter and 1/4″ thick. Naturally, shipping cost more than the parts themselves.

8020 will cut extrusions to length and tap them, so I entered my cut list and my list of hardware, including bolts, captured nuts, brackets, and so forth. Shipping was reasonably fast, even considering the holiday season and associated delays. Between eBay and 8020, I spent about $160, including shipping. Given that many similar jigs on offer are upwards of $1,000, I was pretty satisfied with the price.

In order to convert the discs into a central hub and turntable, I had to drill and tap them. I simply drew them in CAD, then printed full scale. I then used the print as a template, and center-punched each hole. In this manner, I was able to accurately line up the holes in the center hub at 120-degrees, and to offset the axle holes from the pivot point of the turntable. After drilling to size, I tapped them to 5mm/.8, 12mm/1, and 15mm/1.5 using taps I had on hand.

During the process, I also got too clever for my own business, and drilled and tapped holes in the central hub for storing axles, but since my design has a short center post, there isn’t enough clearance for them. I also could have spaced the twin base bolts slightly farther apart to clear the captured nuts a bit better, but in this case, an additional 1-2mm was all I needed. It still worked fine. If I were to build a new one, the lower disc might be better at 6″ diameter, then it would have room for axles. The odds of a rebuild are slim-to-none.

Assembly took only a few minutes, including adding roller bushings to support the rim. I also added 2 aluminum tubes, mounted to the center post, to hold spoke (not shown). Also not shown in the photos is a 3″ tab attached to one of the legs, which can be clamped into a bench vise. The height of the jig was designed on the bench vise plus workbench height in mind, which brings the center of the hub to about 45″ off the floor. If you decide to create a similar jig, you can decide if you intend to sit or stand, and how high the work area should be for comfort.

Basically, with a few dimensions in hand, a few minutes of additional drilling and tapping, and a bit of assembly, and a lacing jig can be had for under $200.

For my jig, the horizontal legs are 400mm, the vertical legs are 180mm, and the center post is 100mm. Almost everything came from 8020, except the 2 discs (eBay) and some roller bushings (local hardware store). You may find that you prefer other angle brackets, bolts, nuts, etc. as you kill time on 8020’s website. I also made tick marks on the legs for different rim diameters and added a silly name and logo to one leg. Basically, I was running out of things to do on the jig, and there was still beer in the fridge.

It’s a fun, easy, relatively inexpensive project, and if anyone actually had spokes, hubs, rims, and nipples in stock, I could actually use it. Maybe in 2023.